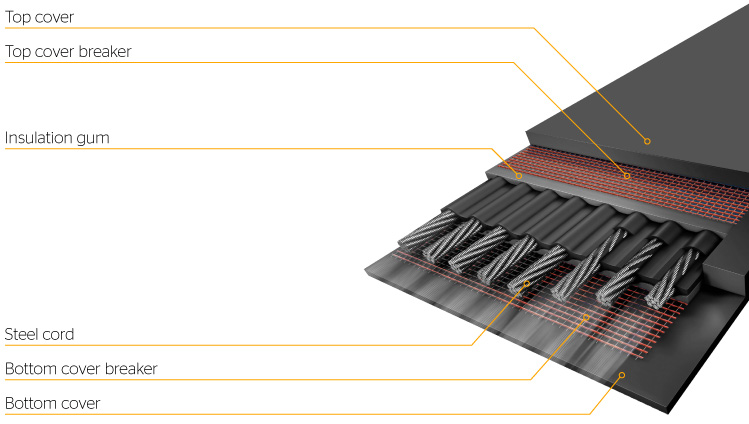

Steelcord Conveyor Belt Construction

The Continental steelcord belt families Phoenix Phoenocord and Flexsteel provide superior impact resistance, with the number and size being selected to meet the desired operating tension and application needs. The insulation gum is specifically designed to encapsulate each steel cord filament to reduce internal friction while providing enhanced adhesion to the cover rubbers. Top and bottom covers provide maximum protection to the steel cord. The cover compounds are specifically designed to meet the demands of the application and are available in a wide variety of rubber types and gauges.

There are four component parts of Phoenix Phoenocord and Flexsteel belting, each one critical to belt performance.

Zinc galvanized steel cord

Phoenix Phoenocord are designed by selecting cord construction to provide the best specification for a particular application. The cords, made up of many wire filaments, are constructed to provide high flexibility, low elongation and permit efficient and high-strength splice designs. The galvanized zinc coating produces a bonding agent between the cord and insulation gum and provides an important barrier against corrosion.

Insulation gum (core rubber)

Extensive rubber compounding technology has enabled Phoenix Phoenocord engineers to develop a superior insulation gum bonding rubber, which penetrates and adheres to the steel cords. The result is excellent adhesions, corrosion resistance and splice efficiencies.

Top cover breaker

Provides additional localized puncture resistance from heavy impact loads that can lead to premature carcass damage.

Bottom cover breaker

Provides additional localized puncture resistance from trapped material that can lead to premature carcass damage.

Outer rubber covers

The advanced compounds in the top and bottom of Phoenix Phoenocord covers are designed to protect the steel cord strength member against the abusive environmental conditions prevalent in most conveying applications. Compounds are available to withstand abrasion, jagged cutting and gouging, high impact, sub-zero temperatures, moderate heat, hardening effects of ozone attack and fire propagation.