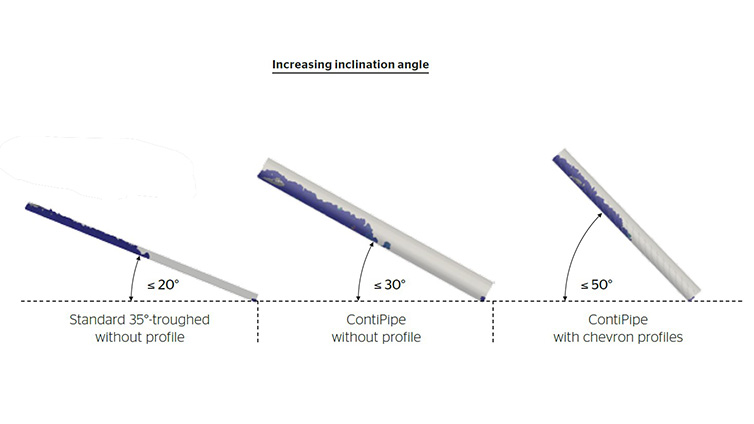

For kilometers, it winds its way over hills, through valleys and sometimes underground. Thanks to its low space requirements and high incline angles, ContiPipe is suitable for companies from a wide range of industries and operating with different types of aggregates. The system’s typical length ranges from between 200 meters and seven kilometers center-to-center distance, depending on the pipe diameter. On their way to their final destination, the conveyor belts take very tight curves, also at high mass flow rates, cope with steep inclines of up to 50 degrees, and adapting perfectly to the local conditions or terrain – both above and below ground.

However, ContiPipe is not only used in applications where the advantages of a pipe conveyor in terms of curves and routing flexibility are important. The system can be also used for various mining and industrial applications, as the closed belt pipes protect the conveyed material against environmental conditions, especially rain, snow, wind and sun. In this way, the extracted material is protected from carryover and adulteration through the removal or addition of material fractions. ContiPipe also protects the environment and people, since hazardous, contaminated, dusty or strong-smelling substances – for example chemicals, waste, ash, overburden – cannot escape.

Excellent service based on extensive experience

“ContiPipe also owes its high profitability and sustainability to the fact that all pipe belts are specifically designed for the respective application. This guarantees ideal running behavior and pipe belt stiffness paired with reduced power utilization based on our eco-friendly compounds,” explains Con Michaels, Director Sales Segment APAC, who serves customers in the European and Asian markets. “Compared to conventional transport by truck, our customers can significantly reduce CO2 emissions. This is environmental protection in the sense of our guiding principle ‘Engineering Green Value’.”

However, ContiPipe, which has been on the market since the late 1980s, does not only owe its sustainable benefits to its design. “Sustainability is supported by a wide range of services,” says Patrick Raffler, Global Product Manager at Continental. “We assist our customers at every phase of their project and support them through planning, installation, commissioning and beyond. Our application engineers can call on many years of experience and extensive knowledge in the field of pipe belt conveyor systems.”

“We are very happy with ContiPipe because the belt has served its said life without any issue or breakdown serving at needed capacity. The response from the Continental service team is prompt and timely making the user feel comfortable.”

Gautam Nayan Upadrasta, Head of Maintenance at Sembcorp Energy India Limited

Services, especially monitoring systems, are very important to keep efficiency at the highest possible level. For two simple reasons: First, because conveyor belts are often subjected to conditions that cause damage, such as trapped material due to spillage, chute plugs, overloading, slip and other common issues. Second, because industrial and mining applications move heavy loads that can be very abusive on conveyor belts.

“Keeping the belt running is crucial for the operator’s efficiency and success,” Raffler explains. “If there is a long-term shutdown of a critical conveyor system, the entire production chain often goes down, resulting in enormous financial losses. To prevent this, we offer various monitoring systems.”

CONTI MultiProtect bundles various smart and sustainable services

One of these monitoring systems is CONTI MultiProtect, a special system scope available in our portfolio for ContiPipe. The technology bundles various smart and sustainable services based on a permanent magnetic system that detects belt rips by monitoring embedded magnetized rip inserts. When using the MultiProtect flat sensor, for example, systems can monitor for steel cord damage and splice integrity in addition to rip monitoring. Another special pipe belt application allows for rip insert functionality to also be used for orientation or rotation. Find out more about CONTI MultiProtect in the video below.

The success of ContiPipe is illustrated, among other things, by numerous long-term customer relationships – and at times also by direct customer feedback. This, for example, includes Sembcorp Energy India Limited, a leading independent power producer in India that has relied on Continental’s ContiPipe systems and service offerings for several years.

“We are very happy with ContiPipe because the belt has served its said life without any issue or breakdown serving at needed capacity. The response from the Continental Service Team is always prompt and timely, making us feel comfortable,“ says Gautam Nayan Upadrasta, Head of Maintenance at Sembcorp Energy India Limited. “We are looking forward to the continuation of this cooperation, as Continental offers the best solutions for continuing to contribute to our business success in the future.”

Back to the overview