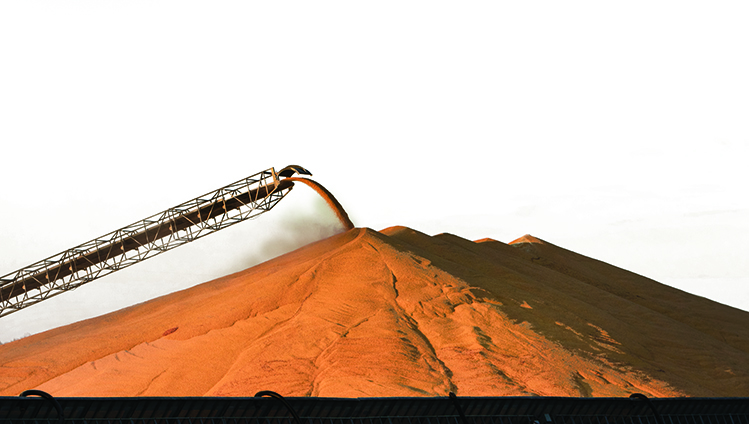

Dispersion of particles into the environment, carryback on the conveyor return run, costs for cleaning belts: Wherever material is transported on conveyors, there are many areas with room for improvement. “With ContiClean, we provide solutions enabling superior material release characteristics for everything from cement to limestone,” says Chris Marchant, Global Product Manager at ContiTech. “These ready-to-use conveyor belts not only help customers reduce the costs associated with cleaning belts and systems, they can also prevent belt damage and improve safety outcomes.”

ContiClean is especially useful for companies that transport very fine material, as Marchant explains: “The finer the material, the greater the difficulty with release when transferring it from one conveyor system to the next. Since the base material after mining, crushing and additives is a fine powder, ContiClean provides a useful solution especially for customers operating in the cement sector. If the system happens to be completely exposed and it rains, it is even more difficult to remove the damp or wet powder.”

Increasing demand and sustainability awareness

Given the strong growth in demand expected for cement and concrete, increased sustainability, efficiency, safety and profitability will play an important role in the coming years. According to current forecasts, demand will increase by an average of two to three percent per year, mainly due to increasing urbanization and investments in infrastructure. Based on these expectations, cement consumption will have almost doubled by 2050 compared to today.

“ContiClean supports the production of cement and other materials in being more sustainable through a reduction of dust-borne air emissions, pollution and waste,” Marchant continues. “In addition to increased efficiency, the positive impact on the environment is of course a feature that helps companies operating in the cement industry reach their sustainability goals. Especially as the awareness for this topic is increasing.”

ContiClean provides a long list of advantages

Standard belt covers and scraper systems may not provide sufficient material release, which can then lead to many adverse effects for production. “Adverse effects resulting from carryback issues include material buildup on pulleys, idlers and belt covers,” explains Marchant. “Any one of these issues can lead to increased cover abrasion, belt alignment problems, belt or system damage and significant increases in the cost for cleanup. All of these contribute to safety and environmental hazards.”

With ContiClean, customers can benefit from increased material transfer, reduced material buildup on pulleys and idlers, increased belt cover and scraper life, reduced maintenance and safety issues, less downtime for maintenance issues, lower operating costs, increased profitability – the list of benefits is a long one.

Positive customer feedback from around the world

The feedback ContiTech receives from its customers is consistently positive, as Marchant points out: “ContiClean is a global solution, with all regions reporting favorable customer feedback. A system installed at a cement plant located in the USA, for example, reduced their carryback issue by 95 percent. Another reported reducing their material buildup on the walkway below by 75 percent. The operator at this plant is incredibly happy with the results. Prior to the introduction of ContiClean, this was a major issue for this site.”

Another customer in Chile that conveys material with sulfuric acid reported a serious problem with material accumulating throughout the system structure. “The customer’s previous experience with a competitor solution was unsuccessful,” says Marchant. “ContiClean’s non-stick release characteristic is present throughout the carry side cover thickness. For this customer, we helped them not only to overcome their material accumulation issue but also to double their conveyor belt service life.”

Benefits in line with Continental’s sustainability ambition

The benefits of ContiClean for customers are also in line with the most important strategic goals established by Continental. By 2050 at the latest, the technology company and its supplier partners strive for carbon neutrality along the entire value chain.

Alongside Emission-Free Mobility and Industry, Circular Economy, and Responsible Value Chain, Carbon Neutrality is one of four major pillars we are building on today and will continue to build on in the future,” emphasizes Marchant. “With these efforts, we are following our sustainability ambition – providing the framework to turn change into opportunities.”