Continental offers various solutions that are customized for safer, faster and more effective conveyor system maintenance. These solutions are typically comprised of a combination of equipment, tooling, supporting engineering and documentation that is largely developed in-house by a team of specialists focusing on conveyor maintenance and service-related activities. The team works with and assists customers’ technical and engineering departments in most disciplines, including mechanical, structural, electrical and automation.

“Engineered solutions are particularly interesting for customers looking for a premium maintenance concept to avoid or reduce downtime,” says Scott Marvelley, responsible for Service Engineering within Continental Conveying Solutions. “This not only enables them to save costs, but also benefit from a safer operating environment and less business risk.”

Jointly developed process significantly reduces downtime

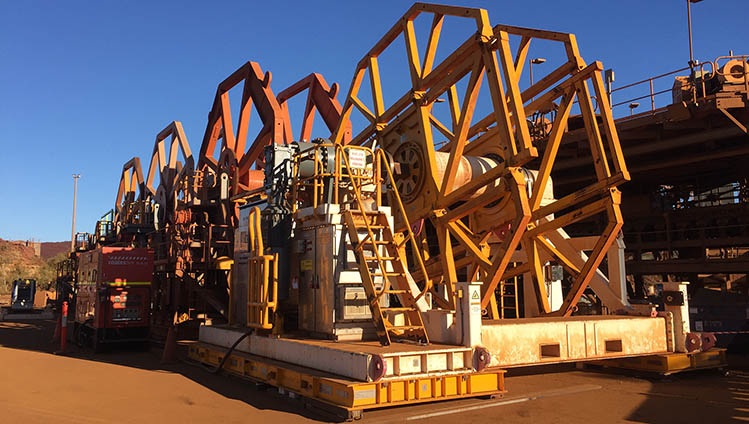

How useful these solutions are in practice recently became apparent in the Pilbara region of Western Australia. “The maintenance team at an iron ore producer was very happy to implement a jointly developed process when our Service Engineering experts said they could complete a major belt changeout in 48 hours instead of the previous 144 hours,” Marvelley reports.

The project required the installation and splicing of 5,460 meters of conveyor belt on a major port feed conveyor system. Several scenarios for the belt replacement program were considered, involving different shutdown options with various methods and scopes of work. “Together with the customer, our Service Engineering experts developed a detailed solution for the safe and efficient replacement of the entire conveyor belt within a defined installation window,” Marvelley explains. “Finally, the belt movement works were finished in just eleven hours – ahead of schedule – thanks to smart solutions, creative thinking and hazard elimination.”

To meet even the most complex customer requirements, the Service Engineering team consists of three sub-groups with different focuses. The design experts are involved in the development of bespoke equipment, structures and systems as required by the customer. The Troughed Belt team members are typically involved in supporting the flat or troughed belt product. The Specialty Belt team focuses on providing support for the customers of Continental products such as Sicon, Flexowell, Pocketlift, automotive belts and others.

A focus on sustainability

The Service Engineering team also supports customers by developing solutions that reduce the environmental impact of their operations and make them more sustainable. “A good example is the large belt replacement system we are currently working on for a key iron ore mining project in Brazil,” says Marvelley. The conveyor is in the middle of a forested area, so the main challenge is to find a solution that would occupy less space. Marvelley: “Given the complexity of this task, the customer is able to benefit from our know-how and innovative approach. Here too, we will successfully manage to deliver a safe and effective solution for this specific belt replacement operation.&rdquo

Back to the overview