It has been 68 years since the first

National Garden Show in Hanover, a colorful exhibition of flowers and plants designed to showcase the best of the gardening trade. Since then, the National Garden Show has attracted lovers of plants, horticulture and landscaping to a different German city every two years. As part of the show, the exhibitors present a variety of flowers, plants and modern landscaping at various urban locations over the course of six months. This year, the National Garden Show is heading to Heilbronn in Baden-Württemberg. Here, too, the exhibition will be integrated in the existing urban concept and is expected to create a greener cityscape that will endure well after the event is over. Existing parks and greenery will be spruced up and new green spaces created. Over one million bulbs were planted across nearly 40 hectares, some even by hand. Fortunately, the National Garden Show team had some mechanical support to help them with other activities.

A total of 600,000 cubic meters of soil were moved within the site, an amount roughly equal to a 600 km line of fully loaded trucks. The people digging the soil found more than 300 metric tons of scrap material, which was separated from the soil using state-of-the-art sieves, meaning that most of the soil could be used again on-site.

Low-noise soil mixture sieving – the knowhow behind it

Community gardeners, horticulturists and landscape gardeners also regularly find scrap material in the soil when they remodel or dig up green spaces in residential areas, parks and gardens. This scrap material can be separated from the soil using specially designed sieves, which should ideally keep noise to a minimum so that local residents are not disturbed and also weigh as little as possible so that they can be transported easily.

To meet these requirements, Massen-Niederlausitz-based company

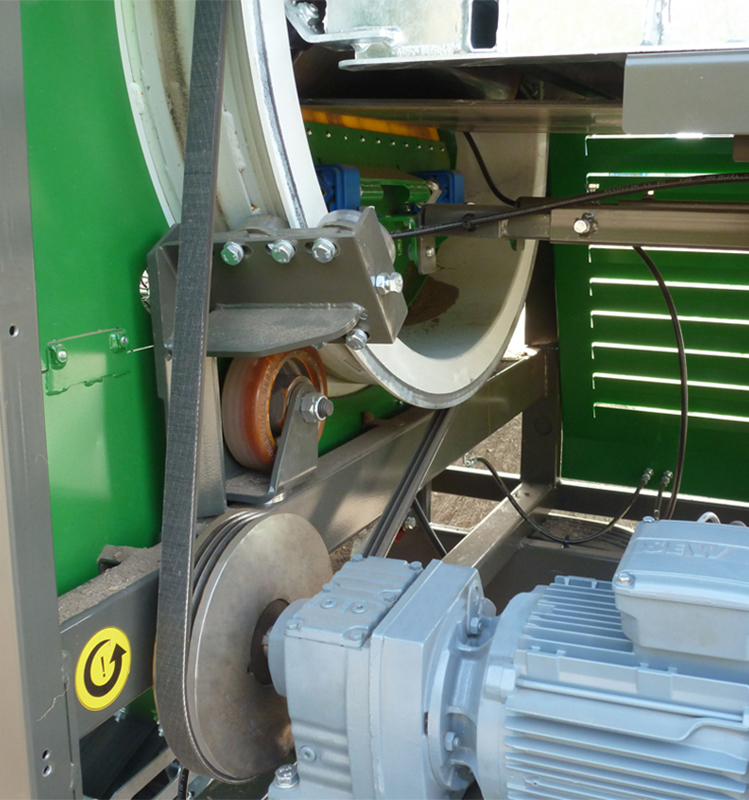

Zemmler Siebanlagen has developed its MS1000 mobile sieving system. Weighing just 1800 kg, it is by far the lightest machine in its portfolio. The Zemmler technicians teamed up with our drive system specialists to optimize the MS1000 drive and came up with a simple yet brilliant idea: Replace the gear rings and chains typically installed in the barrel units with a poly V-belt. “Chains and rings achieve high power transmission and have an extremely robust and reliable design,” said Lutz Jänisch, Service Manager at Zemmler Siebanlagen. “The poly V-belt achieves the same level of efficiency through the looping of the reel and a precisely set pre-tension, allowing the benefits of the belt to really come to the fore: Our poly V-belts, which are produced using elastomers, weigh much less than the current components of the steel chain and gear ring – and run virtually silently.”

Low-maintenance, durable and “streamlined”

In the laboratory, the compact MS1000 proved to be the ideal test vehicle. The Conti-V Multirib poly V-belt was attached to the reel to transfer the torque, allowing it to power the sheave in front of the motor. “Zemmler has taken a new and systematic approach with us here in terms of drives for these systems,” said Roman Schulz, Responsible Application Engineer for Drive Belts at Continental. In addition to a weight reduction of around 40 kg and minimal noise levels, the sieve with belt also offers outstanding durability: “We are confident that the belts will achieve and even surpass the typical service life of the chain, which Zemmler estimates at between 2,000 and 3,000 operating hours,” said Peter Steer, Responsible Regional Sales Manager for Drive Systems at Continental. Maintenance costs are also significantly reduced because, unlike the chain, the belt does not require any oil.

Our drive experts were just as enthusiastic as the Zemmler designers. The MS1000 is now going into limited production. But that’s not all: Zemmler is already planning to use the belt for the next-largest machine.

You can view a video of the field test

here.