Smartphones, vehicles and machines all have one thing in common: they need energy and raw materials in order to be produced and operated. Crude oil, natural gas, precious metals and, not least, coal are therefore in demand around the world. In China, coal serves as a major source for national energy production, making it the most important resource for covering the country’s vast energy requirements. The densely populated country has developed tremendous demand for energy due to its booming economy in recent decades. And there is plenty of coal in China; in particular, the autonomous Inner Mongolia and Shanxi regions in the north of the country have large deposits of the fossil fuel.

Smartphones, vehicles and machines all have one thing in common: they need energy and raw materials in order to be produced and operated. Crude oil, natural gas, precious metals and, not least, coal are therefore in demand around the world. In China, coal serves as a major source for national energy production, making it the most important resource for covering the country’s vast energy requirements. The densely populated country has developed tremendous demand for energy due to its booming economy in recent decades. And there is plenty of coal in China; in particular, the autonomous Inner Mongolia and Shanxi regions in the north of the country have large deposits of the fossil fuel.

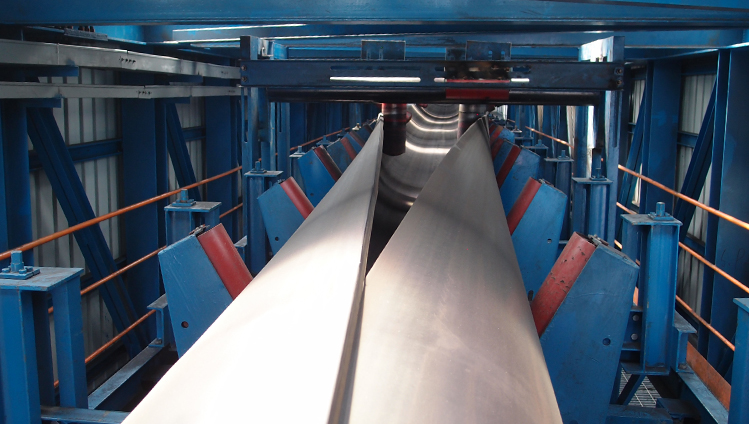

Making coal mining environmentally friendly while at the same time investing in the expansion of renewable energies are important aspects of China’s energy policy. This is where our products come in. A recent example: In Yangquan, the Shanxi region, we are using a closed-trough conveyor belt system to ensure the smooth and environmentally friendly extraction of pit coal. It negotiates an 8.1-kilometer route on rugged terrain with height differences of up to 172 meters – and is one of our longest closed-trough conveyor belt systems in China.

Better air and greater safety

Many mine operators are already using our closed-trough conveyor belts, otherwise known as pipe conveyor belts. In general, conveyor belts are the financially and environmentally more advantageous transport solution within a certain distance compared with alternatives such as truck fleets, since their operation emits less CO2 and there is no need for empty trips. Closed systems such as tube conveyors offer other decisive benefits. They minimize dust emissions and the conveyor belt is well protected against environmental influences. This also impressed the operator of the coal mine in Yangquan, YanKan Coal.

Many mine operators are already using our closed-trough conveyor belts, otherwise known as pipe conveyor belts. In general, conveyor belts are the financially and environmentally more advantageous transport solution within a certain distance compared with alternatives such as truck fleets, since their operation emits less CO2 and there is no need for empty trips. Closed systems such as tube conveyors offer other decisive benefits. They minimize dust emissions and the conveyor belt is well protected against environmental influences. This also impressed the operator of the coal mine in Yangquan, YanKan Coal.

It is estimated that coal dust emissions caused by gusts of wind, snow and rain amount to 0.12 percent of transported materials when open conveyor systems are used. In Yangquan, our tube conveyor, with a width of 1,600 mm and an outer pipe diameter of 458 mm, transports 1,000 metric tons of coal per hour and 2.4 million metric tons of coal per year. “This results in an enormous saving of 2,880 metric tons of coal dust emissions, significantly improving air quality. Thus, our system also protects the health of mine workers and improves the quality of life of the people living in the area,” explains Stephan Weisgerber, an employee based in China. Our technology also helps meet stringent safety regulations for coal mines that dictate the maximum concentration of dust in the air. Moreover, the closed-trough conveyor belts are fireproof.

|

Stephan Weisgerber is a specialist for conveyor belts and is working on site in China:

“Our closed-trough conveyor belt system results in an enormous saving of 2,880 metric tons of coal dust emissions, significantly improving air quality.”

|

Energy-efficient conveyor belt system saves on costs

In terms of efficiency, the system scores points with its speed and energy requirements. Miles of conveyor belts can consume as much electricity as a small town. Our solution: “With a special material compound that minimizes rolling resistance, we were able to reduce the energy consumption involved in transporting raw materials by 25 percent. This will improve the facility’s carbon footprint and save on energy costs,” says Weisgerber.

Our closed-trough belt conveyors have already proven themselves in many places in China – in coal mines as well as in power plants and steel mills - and further projects are being planned. The challenge was that every conveyed good requires its own conveyor system engineering. We work to find the right solutions for every application.