More and more vehicle manufacturers are focusing on alternative drives to provide sustainable mobility solutions. In 2020, 10.3 million new registrations of electric cars and plug-in hybrids are predicted worldwide. By 2030, it will increase to 54.3 million (source: statista). Alongside the growing number of electric and hybrid vehicles, the demands on components and materials are increasing. In our TechCenters, we develop plastic-based innovative solutions contributing to a more efficient and sustainable mobility of the future.

More and more vehicle manufacturers are focusing on alternative drives to provide sustainable mobility solutions. In 2020, 10.3 million new registrations of electric cars and plug-in hybrids are predicted worldwide. By 2030, it will increase to 54.3 million (source: statista). Alongside the growing number of electric and hybrid vehicles, the demands on components and materials are increasing. In our TechCenters, we develop plastic-based innovative solutions contributing to a more efficient and sustainable mobility of the future.

Tubes and hoses are lifelines of mobility

In the age of electro mobility, lines and hoses are indispensable. Unlike conventional vehicles, electric and hybrid vehicles require cooling circuits featuring sophisticated thermal management. Since batteries need to be cooled or heated depending on the outside temperature, better thermal management means longer and more efficient operation and thus longer ranges. Additional potential lies in plastic lines. In hybrid or electric drives, fluid systems made of rubber or stainless steel are increasingly replaced by high-performance plastics. Plastic components reduce vehicle weight and thus contribute to lower fuel consumption and CO2 emissions - while improving performance.

|

Dr. Maximilian Schöngart, head of pre-development for plastics technology, works on innovative plastic solutions for electric and hybrid vehicles:

„By integrating sensors into our products, we want to collect and use additional data and information from heating and cooling circuits in the future. This data can optimize the entire energy management of the vehicle and reduce emissions.” |

|

Plastics expertise at specialist TechCenters

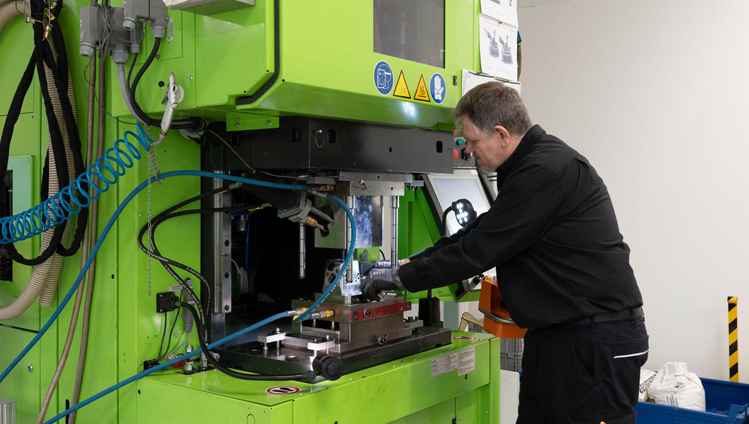

In five TechCenters in China, North America and Germany, we research and develop the mobility solutions of tomorrow. The material experts at our TechCenters in Germany work together across all locations.

Our specialist TechCenters are comprehensively equipped highly flexible and fully production-capable systems in which we research and test technologies or innovations, bundle our know-how and offer the entire development process chain. The TechCenters are exclusively available for new developments. Only high quality and mature solutions enter the factory for production. This means that our automotive customers benefit from faster and more targeted developments – a clear advantage over trials during ongoing volume production.

Our specialist TechCenters are comprehensively equipped highly flexible and fully production-capable systems in which we research and test technologies or innovations, bundle our know-how and offer the entire development process chain. The TechCenters are exclusively available for new developments. Only high quality and mature solutions enter the factory for production. This means that our automotive customers benefit from faster and more targeted developments – a clear advantage over trials during ongoing volume production.

Sensor integration for optimal thermal management

Plastic lines offer a high degree of design freedom and are therefore extremely well suited for the future integration of functional parts such as sensors. In our TechCenters, we therefore combine new materials with innovative sensor technology, for example, to allow ideal thermal management. Sensors and digital applications can thus ensure optimum energy consumption, low emissions and high driving safety in the future.