A ticket to the moon and back, please! What sounds like a line from a science fiction novel is actually part of everyday life on German roads: buses in this country travel around 800,000 kilometers before they are taken out of service – so a trip to the Earth's satellite would be no problem. In the future, e-buses are expected to last just as long. This poses a major challenge for manufacturers – and not just in terms of batteries and powertrains. For the virtual trip to the moon, the manufacturers rely on Continental's experience in engine mounts and air springs.

Not all springs are created equal

The big driver of innovation in buses has always been the truck sector. Even when it comes to the switch to electrified drives, buses can learn a lot from trucks, because the basic design is similar and the engines used are usually the same. So it's only natural to think that other components, such as mounts and air springs, could also be adopted one-to-one. However, it is not quite as simple as that, because the requirements placed on the springs are too different.

Basically, the air springs in buses and trucks ensure that the vehicle, load and passengers travel safely and comfortably – especially in poor road conditions. The compressed air filled in the rubber sleeve of the air spring cushions the vehicle in traffic and raises the vehicle to the correct ride height. This is one of the biggest differences between trucks and buses: the springs in trucks are usually designed for large spring deflections to compensate for height differences, for example at loading ramps or when loading containers. In contrast, shorter springs are used in city buses. A positive side effect is that the passenger compartment above can be designed with more space and freedom, and the technical development challenge lies more in the higher comfort requirements.

In the case of the all-electric bus, there are additional factors: because of the batteries, it is heavier than a diesel bus. And because they are located on the roof, the center of gravity is much higher.

Made to measure from a modular system

Even if a one-to-one transfer from the truck is not possible, an expensive new development of Continental’s air springs is fortunately not necessary with either. This is because, as with a modular system, all the necessary changes to existing components can be made quickly and easily during development to ensure the right service life, ride comfort and safety. This means, for example, that the structure of the air springs and the materials can be individually adapted to the city bus, the sleeve can be adjusted accordingly, and the piston contour can be changed. Virtual simulations are also used to test the performance of the adapted air springs, which saves valuable development time on the way to fully electrified public transport.

Defying the discords

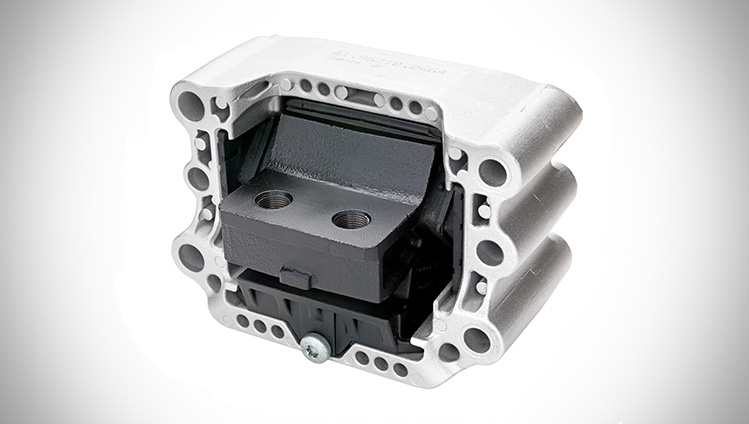

For this, e-motors are important trailblazers and their mounts therefore have an important role to play. However, buses and e-motors are a challenging combination. This is because, as with air springs, the requirements for engine mounts in e-buses are quite different from those for combustion engine buses or electrified trucks. In an internal combustion engine, for example, the main task of the engine mount is to secure the unit in the vehicle in such a way that its vibrations are not passed on to the body – otherwise a ride would quickly become very uncomfortable.

Vibrations also occur with the electric motor, but they are hardly noticeable. Instead, there is a different phenomenon here: the high-frequency vibrations of the e-motor can excite surrounding body parts and cause them to vibrate. If the vibration is strong enough, it results in unpleasant whistling and booming noises. In contrast to the loud combustion engine, these noises are much more noticeable in the quiet e-drive.

Continuous strain in city traffic

Again, the first impulse might be to reach into the truck storage rack to solve these problems. In fact, however, the engine mounts for the e-bus requires expertise from both the car and truck sectors. The e-motor is basically the same as in the truck, but the driver's cab is decoupled. Therefore, there is an additional buffer between the engine and the body that can absorb vibrations. In the electric bus, on the other hand, the engine is directly connected to the body. What's more, because of the much larger resonance surfaces that can begin to vibrate in the bus, even the large side windows can unintentionally become a loudspeaker.

In addition to the different acoustic conditions, the electric motor is subjected to very different demands in buses or trucks. In the city bus in particular, the mounts are subjected to particularly high loads due to the start-stop traffic. In the case of the e-bus, this is compounded by recuperation, i.e. the recovery of energy while driving. Coupled with the very high torque of the e-motors, the demands on the engine mounts are enormous. Every rubber compound reacts differently under such a high continuous load. If the wrong mix is used here, the service life of the mounts suffers enormously. But here, too, manufacturers benefit from the very broad Continental product portfolio, from which the right engine mounts can be quickly provided – from the right geometry to the right material mix.

The future will be lighter and reach further

In the medium term, the aim is not only to save time in development, but also weight. After all, every kilogram less in an electric bus equates to a gain in range. One possible way to achieve this is to rethink materials, especially the air spring piston. This is usually made of steel. An alternative is the plastic piston. "An air spring piston has to withstand great forces. When the word plastic is mentioned, the first thing that comes to mind might be a brittle part. But we're talking about pistons made of glass-fiber-reinforced high-performance plastics that are just as resilient as steel pistons," says Axel Szyszka. "In the truck sector, the plastic piston has proven its worth in recent years, so it is also becoming increasingly interesting for buses. E-buses in particular would benefit from a weight saving of around 30 percent in air springs."

In the e-bus of the future, mounts are also expanding their literally supporting role: in the past, auxiliary units such as the air or air-conditioning compressor were usually attached directly to the heavy internal combustion engine. With the lightweight e-motor, this is hardly possible. In the future, the smaller units will have to be mounted independently. It would also make sense to mount the batteries so that the vibrations of the battery packs, which weigh several hundred kilograms, can be better controlled. This not only offers a clear plus in terms of safety, but also protects the bodywork – and thus extends the service life of the bus. And after the trip to the moon and back, there might even be a trip or two around the world left in it – if you've bought the right ticket.