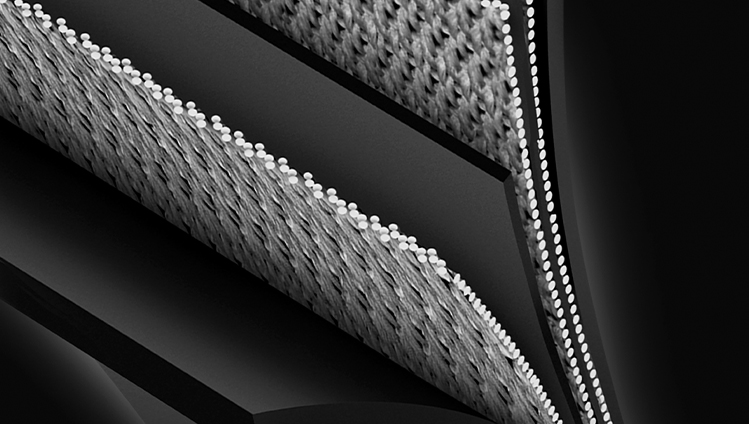

Continental cover compounds provide the ultimate protection for your belt carcass so that you realize a lower cost-per-ton conveyed and your system requires less maintenance. Our innovative, thermoset-formulated compounds provide protection and performance in even the toughest applications. Utilizing our compounding expertise, we offer a wide variety of cover compounds to meet your specific application requirement.

Our manufacturing process is vertically integrated and unique to the conveyor belt industry. Backed by extensive research and testing facilities, we have cover compounds to meet your rigorous requirements. We own mixing facilities that provide raw materials used in making our cover compounds, giving us more control over the quality of the product every step of the way.

Standard Compounds

Alumina – HOT

Specifically designed compound intended for usage at alumina facilities where alumina material temperatures range up to 400 °F.

Arctic Gold and Arctic Gold Plus

Excellent mineral oil and abrasion resistance combined with improved low temperature properties.

Defender and Defender Plus

DIN Y and ARPM Grade I rubber compounds designed to provide very good abrasion resistance, good gouge resistance and excellent flex life.

Eco Series

Low rolling resistance compounds designed to reduce energy loss through indentation of the pulley cover. This occurs through contact with conveyor idlers. With hundreds of kilometers of belt in operation benefitting from Eco Plus, which provides up to 15% reduction in energy consumption and Eco Extreme providing as much as a 30% reduction when compared to standard compounds.

Shield FR-2G, Shield FRAR-2G & Shield FRHT-2G

Flame resistant series of compounds designed especially for aboveground prep plants, power plants and non-coal underground mining applications that require ASTM D378-13.2 (old MSHA CFR 30 part 18) flame test standard. For applications requiring moderate heat resistance up to 250 °F, FRHT-2G is available.

Shield ARMA Plus & Shield ARMA Tough

Designed for the underground coal mining market, it meets the MSHA CFR part 14 (B.E.L.T.) flame standard. Shield ARMA compounds are ozone resistant and offer great abrasion resistance for the most demanding applications, including slope belts.

Shield FRORS-2G

Resistance to oil and static conductive, this compound is designed for oily coal or coke materials in areas with fire dangers. FRORS-2G meets ASTM D378-13.2 (old MSHA CFR 30 part 18) flame test standard.

Shield FRAR-CSA C and Shield FR-CSA C

Fire-retardant anti-static belting is certified by the Canadian Department of Energy, Mines and Resources, Ottawa to CAN/ CSA M422M87, Type C, for below surface use as well as othermining operations. FRAR-CSA C offers approximately 40% better abrasion resistance than FR-CSA C compound.

Easyrider

(DIN Z and ISO L) rubber compound designed to provide abrasion resistance and very good flex life.

Monster Hide, Monster Hide Plus and Monster Hide MORS

The ultimate in cut and gouge protection. Designed to absorb impacts from large rock with sharp edges. Monster Hide MORS resists the effect of cover cuts and chunking associated with localized heavy impact and is MOR-resistant to cover swell associated with terpene oil.

Gold Classic, Gold Plus and Gold Extreme

Gold series compounds protect from the effects of terpene in wood chips, oil grains, and petroleum oils. Gold oil compounds offer good abrasion resistance and great value for handling moderately oily material where fire resistance is not required.

Pathfinder Supreme, Pathfinder Arctic and Pathfinder CSA

Flame retardant compounds designed especially for the grain industry where oily grains and controlled mineral or vegetable oil dust suppressive spray come in contact with the belt. Pathfinder Arctic for low temperature requirements to -40 °F (-40 °C).

Solar-Shield Gold

An oil-resistant compound formulated for applications demanding higher resistance to heat, oil and abrasion. It is resistant to temperatures up to 350 °F (180 °C), oxidation and the effects of corrosive atmospheres.

Solar-Shield Classic, Solar-Shield Plus,

Solar-Shield Extreme and Solar-Shield Ultimate

An exceptional range of hot material compounds when superior heat resistance against hardening and cracking is required. Solar-Shield compounds are designed to carry hot material at intermittent temperatures from 350 °F (180 °C) with Classic, up to 750 °F (400 °C) using Extreme and over 750 °F (400 °C) using Ultimate and retain its superior heat-resistant qualities.

Stacker (DIN W, ARPM Grade I)

Stacker Plus (ARPM Grade I, ISO H, DIN X, ASM, SANS M)

Premium compounds designed for excellent resistance to cutting, gouging and abrasion.

Survivor (ARPM Grade I, AS-A, SANS A)

Survivor Plus (ARPM Grade I)

Designed for superior abrasion resistance. Ideal for high-speed, small diameter crushed stone, trap rock, ore, copper, taconite and other abrasive applications where performance matters.