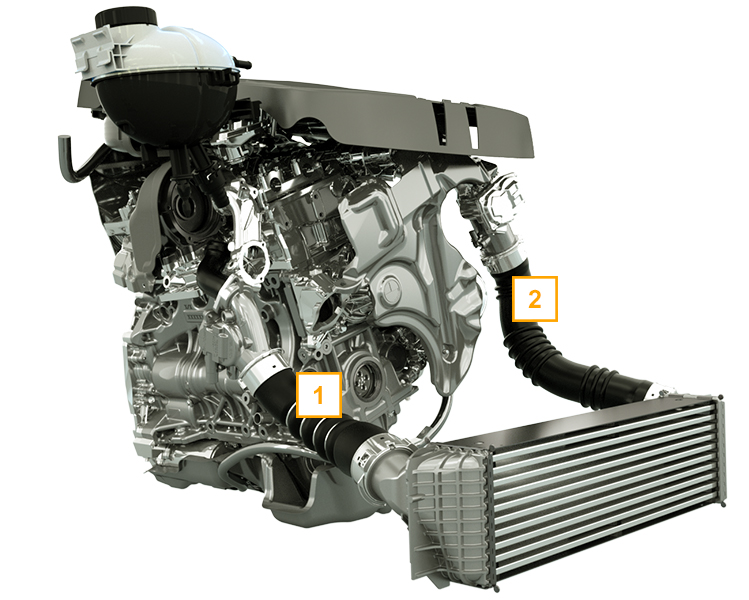

Air Management Around the Turbocharger

The downsizing of engines is placing increasingly stringent demands on turbocharger lines. By literally injecting some “fresh air”, our charge air line system is able to safely generate a high power output.

Our charge air systems are developed and manufactured in Asia, Europe and North America on the basis of a global project management standard. Our extensive in-house compounding expertise allows for the optimum combination of materials, which can be supplemented with electronic components.

For various passenger car applications - for example, use between the engine and the charge air cooler or the charge air cooler and air intake manifold - we manufacture extruded and wrapped hoses. Our short, highly flexible molded hoses (Ultraflex) do the trick wherever complex clearances combine with increasingly stringent requirements in terms of pressure, temperature and dynamics. Our 3D blow molded and injection molded charge air tubes are especially popular thanks to the savings they offer in terms of weight and cost. Resonators provide additional optimized acoustic properties.